Case Studies

New & Used Cooking Oil Case Study

Cooking oil is a vital component to many restaurants, allowing them to craft stir fries, deep fry tasty chicken, and deliver batches of hot, crispy fries to diners. But managing the flow of new and used cooking oil is a constant cycle each restaurant must balance, and that’s where a cooking oil collection company comes in. These collection companies provide services that can help restaurants manage the flow of new cooking oil coming into the building while also offering responsible disposal of used cooking oil. One such collection company was able to effectively manage their operations with the help of an ultrasonic level sensor and a customized system from Automation Products Group, Inc. (APG).

Challenges: Wasted Time

As the collection company goes from restaurant to restaurant, it supplies them with new cooking oil. Any collected used cooking oil is taken and transported to a facility where it’s repurposed into fuel. It’s a waste of time to visit a restaurant too soon or too late to change their cooking oil. Needing fresh oil is a task that can be overlooked by staff, which could lead to supply mismanagement and even issues with serving diners in the restaurant without fresh oil. The collection company had to find a way to monitor cooking oil levels, whether fresh or used, and determine when their customer needed their services at the right time.

A Customized Solution

The collection company turned to APG and our MNU ultrasonic level sensor, a Modbus ultrasonic level sensor that was integrated into a larger overall system. The MNU has remote configuration and monitoring compatibility, allowing the collection company to track cooking oil levels.

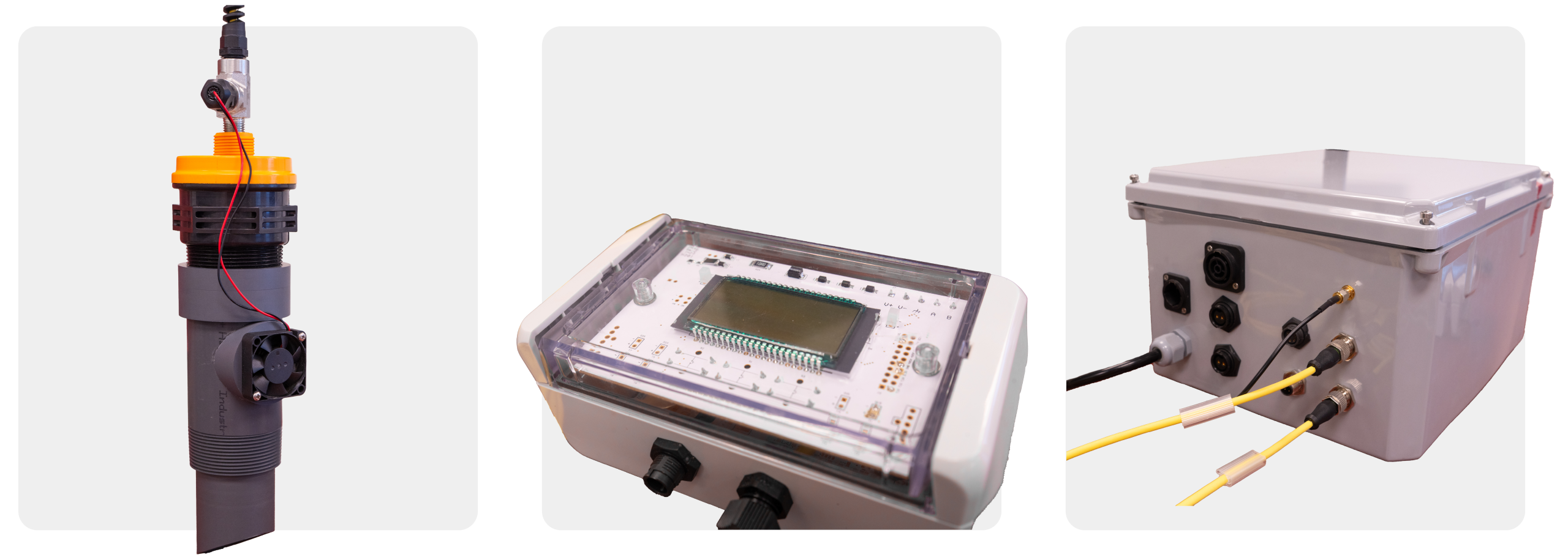

APG supplied a communication system with a switch, a containment box, and display alongside the MNU ultrasonic level sensor. The MNU was installed inside tubing with hot cooking oil and limited air flow, so after a few tests done by our team a customized fan was placed inside to prevent the sensor from overheating. The set up was straightforward, with easy installation and assembly, and allowed the collection company to quickly install the system into restaurants.

The MNU ultrasonic level sensor monitored the oil levels of two different holding tanks: one with used cooking oil and one with new cooking oil. The MNU triggered alarms in the system when the new cooking oil tank fell to lower levels, or when the used cooking oil level became too high. These alarms alerted the collection company and let them know exactly when to visit a restaurant to supply or remove cooking oil as needed preventing unnecessary trips.

With the MNU ultrasonic level sensor and their customized system from APG, the collection company was able to keep track of cooking oil, either used or new, and plan their collection routes ahead of time for efficiency. The restaurants they served were able to focus their time on needed tasks, and got their cooking oil when they needed it. This customized system was simple to install, with straightforward components, allowing for quick and easy set up.

If you’d like to know more about how APG can customize a solution for your specific operations that are tailored to your needs, reach out to us today!

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.

COLLABORATING AUTHOR

Daniel B.

Daniel Bardwell is a Senior Mechanical Engineer at APG. He graduated Utah State University with a bachelor’s degree in Mechanical Engineering. Having been in sensors and sensing technologies for over 20 years, he has extensive experience with process measurement, especially in hazardous locations. Daniel enjoys watching movies and spending time with his family in his free time.