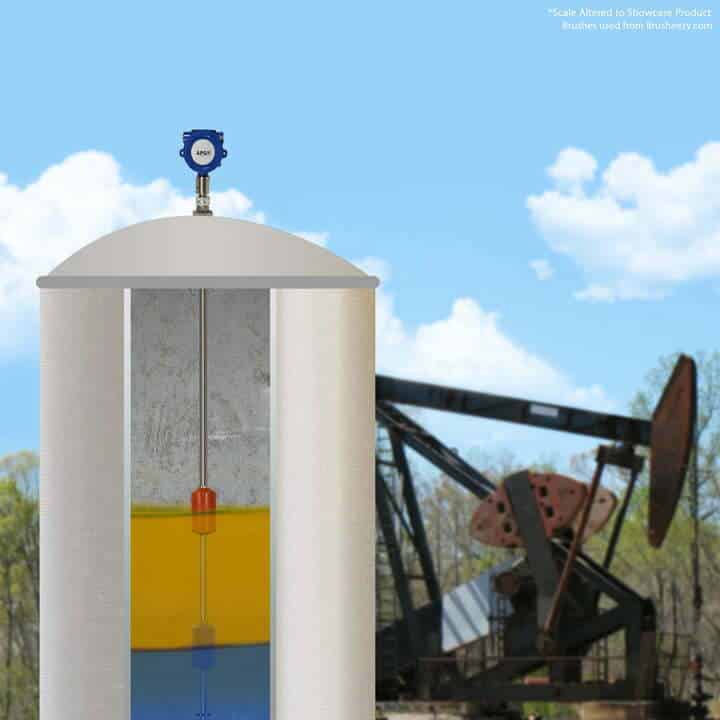

Explosion Proof Rugged Magnetostrictive Level Sensor

MPX-R

Rugged Design with Robust Floats

The MPX-R is a rugged, explosion-proof level sensor designed for the most demanding liquid measurement environments. Engineered for harsh conditions, the MPX-R features large, buoyant floats and a durable stem—ideal for applications prone to heavy fouling or buildup. It provides highly accurate, repeatable readings of both interface levels and total volume, making it a reliable choice for oil & gas, petrochemical, water treatment, and other industrial settings.

The MPX-R supports both Modbus RTU (RS-485) and 4–20 mA outputs for seamless integration with any Modbus controller or PLC. It also works with Settler and Explorer, enabling secure, remote monitoring over the Internet.

- Hazardous Area Certification: Certified for Class I Divisions 1 & 2, Groups C & D, Class I Zone 1, and Class I Zone 2, ensuring safe operation in hazardous environments with combustible gases or vapors.

- Versatile Output Integration: Offers 4-20 mA and RS-485 (Modbus RTU) outputs for seamless integration into PLCs, SCADA systems, and industrial automation platforms.

- Durability & Longevity: Rugged design measures up to 31.5 feet (9.6 m), ensuring reliable performance in diverse industrial environments with minimal maintenance.

- Supports Dual-Level Interface Measurement